Importance of the Exhaust Valve in Main Engine Performance

Main Engine Exhaust Valves These are primarily responsible for the gases released by combustion in the engine. Basically, Topu intake valve exhaust valve are responsible for tasks that range from controlling back pressure build-up to reduce emissions by optimising an engine's performance. Consequently, it is very vital that exhaust valves are replaced and serviced accurately.

Exhaust valves have the very important duty of making sure that engine (crankshaft in reality) reaches it's correct rpm range. Airflow rates are controlled via the correct opening and closing of these exhaust valves, which in turn affect engine power. Furthermore, proper exhaust valve timing is essential for keeping the pressurized gases from pushing back into the cylinder during combustion. Incorrect valve timing is serious, reducing power output and can cause increased fuel consumption, as well as knocking.

A common issue that arises with exhaust valves is the wear and tear of valve springs. The springs are subjected to thermal and mechanical stress that can cause deformation and fatigue over time. As valve springs wear they can fail to close the Topu intake exhaust valves completely which lowers compression, reduces power output and increases emissions.

Carbon deposits on valve stems are common in engines that burn a lot of oil, not an uncommon problem either. This results in carbon deposits that hinder the motion of valve and ultimately reduces the power output.

Passage of the valve stem inside the guide, when it is excessive by its newness in a cylinder head component will be another nuisance. Excessive clearance can lead to undesired movement of the valve during operation and result in damage to the valve, seat or guide. On the other hand if there is not enough clearance, it can overheat and seize due to friction.

The effect of exhaust system on efficiency in running environment around the main engine efficient increment

One method aligned with increasing main engine efficiency is exhaust-flow zealotry. Good exhaust valve design, and fitment for best performance; Small valves can choke off exhaust flow, raising engine back pressure and decreasing fuel economy. Alternatively, oversized valves can result in improper sealing and cause exhaust gasses to escape the valve.

Furthermore, the selection of valve material is also important. Stainless steel and titanium are used to make the exhaust valve materials resistant to high temperatures, more robust, less prone of corrosion.

Factors to consider when choosing the right exhaust valve for your auxiliary engine

Valve Material: As was mentioned the Topu exhaust and intake valve material has a big impact on exhaust valve performance. Material selection is a function of the engine type, operation conditions and desired performance. Stainless steel is a favorite choice because of its great corrosion resistance and lasting properties.

Valve Size: Exhaust valve size is another important part of exhaust valve design. Ensures the free flow of exhaust gases, keeps the pressure in front and ensures optimal engine performance by properly sizing.

Valve Configuration: The design of the valve impacts airflow rates The greater the efficiency of how these gases are able to expel itself, will help increase power due to lower backpressure.

New developments in exhaust valve technology are focused on increasing engine performance, lowering emissions and improving efficiency. Electronic exhaust valve control is one of the most noticeable. Electronic control systems use sensors to monitor how the engine is running and adjust exhaust valve timing and lift as required. This intake valves and exhaust valves guarantees the best possible engine performance and reduced emissions.

The usage of materials like Graphene in valve design is the other noteworthy innovation. With exceptional strength, stiffness and durability features thanks to graphene reinforcement it is suitable for high temperature applications.

Finally, exhaust valves are vital to main engine performance. Good installation and routine maintenance are essential to maximize engine performance, increase efficiency while minimizing emissions. An examination of typical problems with exhaust valves, how to improve the flow in a valve and which valve meets your performance requirements are fairly worthwhile subjects. These news Topu valves exhaust, using electronic control systems and even graphene offer promising ways for improved engine performance in the future.

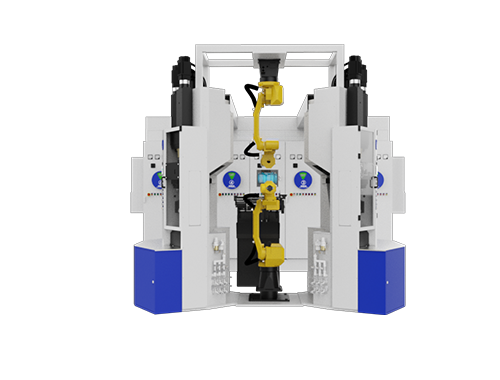

Product quality is cornerstone of Topu's growth. Topu's manufacturing facility equipped with designs and development of products and quality control, as well as Exhaust valve main engine warehouses, among others. The products are controlled strictly line with OEM requirements and IATF16949 system requirements. This includes manufacturing, testing, as well managing warehouses.

Topu continually improves efficiency of its production improves the quality of its products optimizes product structure. It is in line with the high standards set by its partners through using cutting-edge production technology Exhaust valve main engine in engine area. This partnership model allows Topu to provide custom solutions, providing better faster services that are specifically tailored to the requirements preferences each customer.

Topu provides a range products and service simplify the purchasing experience of its customers. When it comes to sourcing components managing logistics, Topu handles every aspect of the procurement process with professionalism expertise. With a single-stop solution, customers can enjoy economies of scale and cost savings in addition to increased efficiency. Topu's integrated purchasing services enable customers streamline their processes as well as reduce administrative burdens, allowing them to focus core business Exhaust valve main engine.

Topu offers diverse selection of products, Exhaust valve main engine customers flexible options well as a broad selection of products. We offer low minimum orders that allow customers place orders according to requirements and not have to worry about stock building up or costly purchase costs. We are also committed to ensuring customers receive their products promptly. The comprehensive approach service is designed to provide convenience and efficiency to customers, helping them better adapt market developments and maintain their edge in the market.